|

| Vehicle Chassis and Body |

In line with the development and advancement of automotive technology, the number of vehicles is also growing, which is made with varying technologies and components with materials that also progressing. Vehicle parts outline is divided into two major groups, namely the Vehicle Chassis and Body.

Definitions Chassis

Chassis is a framework that serves as the support of weight and load of vehicles, machinery and passenger. Frame chassis is usually made of iron / steel that serves to hold the body and engine of a vehicle engine. The main requirement that must be met is the material must have the strength to bear the weight of the vehicle. The chassis also serves to keep the car remains rigid, rigid and do not undergo bending or deformation of time is used.

Type Type Chassis

Ladder frame

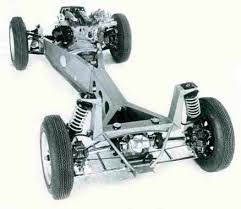

|

| Ladder Frame |

Ladder Frame named because its shape resembles a ladder. Ladder frame chassis which is the oldest and widely used especially for heavy laden vehicles (heavy duty). The chassis is usually made of steel material or model symmetrical beam which is then strengthened with joint cross and joint members. for some designs sometimes Ladder frame given iron reinforcement crosswise in order to maintain structural rigidity.

Monocoque

|

| Monocoque |

On the chassis of this type of vehicle body serves as a chassis, so that its shape depends on the model of the vehicle itself, Chassis monocoque or we often hear the name of monocoque chassis, its main strength is in sheet steel sheet / composite united or strengthened. In adults, this kind widely applied to the monocoque chassis is lighter because the vehicle has the advantage of which could save the use of materials other than it can shorten the production process. because it does not need to make additional chassis instead.

Tubular space frame

|

| Tubular Space Frame |

The chassis uses various types of beams or pipes are assembled into one and the construction was almost like out of the vehicle. The chassis is usually widely applied in the world of car racing, chassis type is very easy to plus or in the design and given additional reinforcement. In this type of structure is very important to make sure all areas of the pitch triangulation (try to observe the horse in a house or a bridge where all the structures created by the connection triangle model. The strength of the chassis is very dependent on the quality and the quality of welded joints of each joint.

Backbone Chassis

|

| Backbone Chassis |

The idea was to make the front and rear structures are connected by a tube that ran along the frame of the car. Unlike the transmission of tunnels, is almost entirely backbone chassis is a rigid structure and can withstand all the loads. There are some holes continuously. Because it is so narrow walls are generally made thicker. Backbone chassis has the stiffness of parts of the backbone area itself.

Aluminium Space Frame

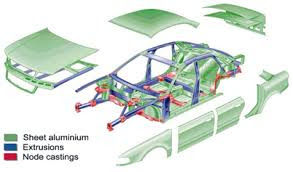

|

| Aluminium Space Frame |

The chassis of this type were first developed by Audi car company (a subsidiary of the VW Group) together with the aluminum manufacturer Alcoa. Aluminum Chassis Frame made to replace the steel monocoque chassis due to produce a lightweight frame. It is said that the type of Aluminium Space Frame Chassis claimed 40% lighter than the steel frame monocoque but 40% more Rigid / Rigid. The picture is a picture on the chassis of the vehicle belongs to Audi.

Definition Body

Part of the vehicle body is formed in such a way (in general) is made of a metal plate (steel plate) thickness between 0.6 mm - 0.9 mm as a passenger or goods.

Automotive body construction is divided into two, namely:

1. Construction Separated (Composite)

Is a type of vehicle body construction where a separate body and chassis. Linkage / connection between the body and frame using bolts and nuts. To improve comfort during use, then between the body and frame mounted rubber as a vibration damper. Construction of a separate body and frame that provides ease of replacement of vehicle body parts were damaged, especially the lower part of the body or frame break. This construction is usually used in the old type sedan vehicles, passenger vehicles and car transportation of goods. (eg, trucks, buses, pick-ups, etc.).

2. Construction Converge (monocoque)

Construction of the body is a type of vehicle in which the body and frame are arranged into a single unit. This construction uses the principle of eggshells, which is a unified whole so that all of the load is divided evenly to all parts of the skin. The linkage between the body and frame using welding. Because the body and frame together, then the shape may be lower than the composite type so that the center of gravity lower gravity would cause the vehicle more stable. This construction is used in sedans, and even some vehicles MPV (Multi Purpose Vehicle) started implementing construction monocoq body.

Similarly, a brief review of Understanding About Vehicle Chassis and Body, hopefully what is reviewed in this article can be useful to readers, if any, need to be asked, please use the comments field.

0 komentar:

Posting Komentar